If you’re tired of dealing with unsightly cracks in your asphalt, it’s time to discover effective repair techniques. Don’t let those cracks get the best of you – take action!

In this article, we’ll explore the most efficient methods for assessing, cleaning, and filling the cracks in your asphalt. From hot rubberized sealing to cold pour techniques, we’ve got you covered.

Get ready to say goodbye to cracked asphalt and hello to a smooth, durable surface.

Key Takeaways

- Visual inspection of crack width, depth, and length is essential for effective crack repair.

- Choosing the right crack filler based on crack size and weather conditions is crucial.

- Utilizing asphalt patching for larger cracks and heat rubberized asphalt for crack filling are effective techniques.

- Regular preventive maintenance, such as routine inspections and prompt addressing of minor cracks, helps prevent future deterioration.

Assessing the Crack Severity

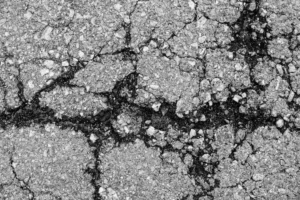

To assess the severity of a crack in asphalt, you should visually inspect the width, depth, and length of the crack.

Start by examining the crack width, which refers to the distance between the two sides of the crack. This measurement is crucial as it determines the type of repair method needed. Cracks with a width of less than a quarter-inch are considered narrow, while those wider than a quarter-inch are classified as wide cracks.

Evaluating crack depth is equally important. You can determine the depth by measuring the distance from the surface of the asphalt to the bottom of the crack. This information helps in selecting the appropriate repair technique and materials.

Cleaning the Cracked Area

Clean the cracked area by removing any debris or loose asphalt. Surface preparation is crucial for effective asphalt crack repair. Before applying any sealant or filler, it’s important to thoroughly clean the crack to ensure proper adhesion.

Start by using a wire brush or broom to remove any loose material from the crack. This will help create a clean surface for the repair material to adhere to.

Next, use a high-pressure air blower or compressed air to blow away any remaining debris or dust. This will further clean the crack and ensure that the repair material bonds effectively.

Additionally, you can use crack cleaning techniques such as pressure washing or water blasting to remove stubborn dirt or vegetation from the crack.

Applying Crack Filler

After cleaning the cracked area, you can begin applying the crack filler to effectively repair the asphalt. When it comes to crack filler application, there are some best practices you should follow to ensure a successful repair:

- Prepare the crack: Use a wire brush or a high-pressure blower to remove any debris or loose material from the crack. This will help the crack filler adhere properly.

- Choose the right crack filler: There are different types of crack fillers available, such as cold-applied, hot-applied, and pourable crack fillers. Consider factors like crack size, weather conditions, and the extent of the damage to select the most suitable one.

- Apply the crack filler: Use a caulking gun or pour the crack filler directly into the crack, ensuring that it fills the entire void. Smooth the surface with a putty knife or a trowel to create a level finish.

Using Asphalt Patching for Larger Cracks

For larger cracks in asphalt, it is essential to utilize asphalt patching techniques. Patching is a common method used to repair significant damage to asphalt surfaces, such as potholes or large cracks. It involves removing the damaged area and replacing it with a fresh batch of asphalt mix. This technique ensures a seamless and durable repair that can withstand heavy traffic and weather conditions.

Asphalt patching offers several benefits over other repair methods. Firstly, it provides a long-lasting solution, preventing further deterioration of the pavement. Secondly, it restores the structural integrity of the asphalt, improving its load-bearing capacity. Additionally, patching enhances the overall appearance of the pavement, making it more aesthetically pleasing.

To further emphasize the benefits of asphalt patching, consider the following table:

| Benefits of Asphalt Patching | Description |

|---|---|

| Long-lasting repair | Prevents further deterioration and extends the lifespan of the pavement. |

| Restores structural integrity | Improves the ability of the asphalt to withstand heavy loads. |

| Enhanced appearance | Provides a smooth and visually appealing surface. |

Hot Rubberized Crack Sealing

One effective technique for repairing asphalt cracks is to use hot rubberized crack sealing. This method involves heating rubberized asphalt to a liquid state and then applying it to the cracks, where it cools and solidifies to create a durable seal. The heating process ensures that the rubberized asphalt penetrates deep into the cracks, providing a strong bond and preventing further damage.

Hot rubberized crack sealing offers several benefits, including:

- Effective crack prevention: The rubberized asphalt forms a flexible barrier that prevents water, dirt, and other contaminants from entering the cracks, which can cause further deterioration.

- Long-lasting results: The rubberized asphalt is designed to withstand heavy traffic and extreme weather conditions, ensuring that the repaired cracks stay intact for an extended period.

- Efficient application: The liquid rubberized asphalt can be easily applied using specialized equipment, allowing for quick and precise repairs.

Saw-Cut and Seal Technique

To further enhance asphalt crack repair, an effective technique is the use of the saw-cut and seal method. This technique involves creating a clean, straight cut along the crack using a saw. The saw cut technique is crucial because it helps to remove any loose or deteriorated material from the crack, ensuring proper adhesion of the sealant.

Once the crack has been cut, a seal coating is applied to fill the void and prevent moisture from penetrating the asphalt. The seal coating acts as a protective barrier, preventing further damage and extending the lifespan of the pavement.

This technique is particularly useful for larger cracks that require more extensive repair. By saw-cutting and sealing the cracks, you can effectively restore the integrity of the asphalt and prevent future deterioration.

Cold Pour Crack Sealing

Now let’s talk about another effective technique for asphalt crack repair: cold pour crack sealing. This method involves using special asphalt crack repair materials that can be applied without heating. Cold pour crack sealing is a popular choice because it’s relatively easy to use and doesn’t require any specialized equipment.

Here are three key benefits of cold pour crack sealing:

- Cost-effective: Cold pour crack sealing materials are affordable and readily available, making this method a cost-effective solution for repairing asphalt cracks.

- Long-lasting: When applied correctly, cold pour crack sealing can provide long-term effectiveness by preventing water infiltration and further deterioration of the pavement.

- Quick application: Unlike other methods that require heating, cold pour crack sealing can be applied directly from the container, saving time and effort during the repair process.

Crack Routing and Sealing

To continue repairing asphalt cracks effectively, let’s delve into the technique of crack routing and sealing, which involves cutting and cleaning the cracks before applying a sealant.

Crack routing is the process of creating a reservoir along the crack to allow for better adhesion of the sealant. This is typically done using specialized equipment, such as a router or a saw. The routing process not only removes debris and vegetation from the crack, but it also creates a clean, uniform channel for the sealant to fill.

Once the cracks are routed, a hot-applied or cold-applied sealant is applied to fill the cracks completely. This sealant helps prevent moisture from penetrating the cracks and causing further damage to the asphalt surface.

Crack routing and sealing is an effective method for prolonging the lifespan of asphalt surfaces by preventing the spread of cracks and preserving the structural integrity of the pavement.

Crack Filling With Asphalt Emulsion

After completing crack routing and sealing, you can move on to the next step of effective asphalt crack repair techniques by filling the cracks with asphalt emulsion. Asphalt emulsion is a popular choice for crack filling due to its versatility and effectiveness.

Here are some pros and cons of using asphalt emulsion for crack filling:

Pros:

- Easy to apply and spread, making it a convenient option for small cracks.

- Provides a watertight seal, preventing water from seeping into the cracks and causing further damage.

- Offers good adhesion to the surrounding asphalt, ensuring long-lasting repairs.

Cons:

- May not be as effective for larger or deeper cracks, as it may not provide sufficient stability.

- Requires regular maintenance and reapplication to maintain its effectiveness.

- Can be more expensive compared to alternative crack repair methods.

Alternative crack repair methods include using hot or cold pour crack fillers, rubberized asphalt, or asphalt-based sealant. Each method has its own advantages and disadvantages, so it’s important to choose the method that best suits the specific needs of your asphalt pavement.

Preventive Maintenance for Crack Prevention

To prevent cracks in your asphalt pavement, regular preventive maintenance is essential. Implementing preventive maintenance measures not only helps to extend the lifespan of your asphalt surface but also minimizes the risk of cracks forming.

One of the key benefits of preventive maintenance is that it allows you to identify and address potential issues before they become major problems. By conducting routine inspections and addressing minor cracks or deterioration promptly, you can prevent them from spreading and causing more extensive damage.

Long-term crack prevention strategies include regular cleaning to remove debris and prevent moisture penetration, sealcoating to protect the asphalt surface from UV rays and oxidation, and periodic crack sealing to prevent water infiltration.

Conclusion

In conclusion, effective asphalt crack repair techniques involve several key steps.

First, it’s important to assess the severity of the crack.

Next, thoroughly clean the affected area to ensure proper adhesion of the repair materials.

After that, apply crack filler to seal the crack and prevent further damage.

For larger cracks, consider using asphalt patching, which is a more extensive repair method. Alternatively, you can opt for hot rubberized or cold pour crack sealing methods, which offer long-lasting results.

There are other effective options as well, such as crack routing and sealing, as well as crack filling with asphalt emulsion.

To ensure the longevity and durability of the asphalt surface, it’s also wise to implement preventive maintenance measures that can help prevent cracks from occurring in the future.