Asphalt pavement is a popular choice for constructing roads, parking lots, and driveways due to its durability and affordability. However, one crucial step that many people overlook is the asphalt curing time. Curing refers to the process of allowing the mixture of asphalt cement and aggregates to harden and reach optimal strength before being subjected to traffic.

Understanding the importance of proper asphalt curing time can prevent premature deterioration, cracking, or deformation in your pavement. In this article, we will delve into what curing means, why it’s essential, factors that affect curing time, how long you should wait before using your newly paved surface, and tips on ensuring successful asphalt curing.

Asphalt Drying Time Vs. Curing Time: The Difference

I’m curious about the difference between asphalt drying time and curing time. Let’s dive into the details of each process and see how they differ. Drying time is the amount of time it takes for the asphalt to become solid and stable after it’s been applied. On the other hand, curing time is how long it takes for the asphalt to completely harden and be ready for use. Both are important steps to ensure the asphalt is properly installed.

Asphalt Drying Time

When it comes to asphalt repair, one crucial step that you need to know is the asphalt curing time. This refers to the period in which the newly applied asphalt undergoes a chemical process of hardening and strengthening. Many people often confuse this with dry time, but they are two different things. While drying time refers to when the surface becomes touch-dry, curing time takes much longer as it involves molecular changes within the material.

The duration of asphalt curing depends on several factors such as temperature, humidity, the thickness of the layer applied, and the type of mix used. Generally, it can take anywhere from 24 hours to several weeks for a complete cure depending on these variables. During this time, any vehicular or foot traffic should be avoided as it may damage the soft surface.

It’s important not to rush through this stage by applying sealant or paint before the asphalt has fully cured. Doing so may result in bubbling or cracking due to trapped moisture underneath. It’s also essential to note that even after a full cure, regular maintenance is required to ensure the longevity and durability of your pavement.

In conclusion, understanding and following proper asphalt curing procedures is critical for achieving optimal results during repairs or installations. Rushing through cure time may lead to costly mistakes down the line. So always consult with an experienced contractor who understands all aspects of asphalt drying time vs. curing time for best practices and outcomes.

Asphalt Curing Time

Now that we have discussed the difference between asphalt drying time and curing time, let’s focus on the latter. Asphalt curing is a crucial step in any repair or installation process as it determines the strength and durability of the pavement. The curing process involves a chemical reaction within the material where liquid asphalt hardens to form a solid surface. This can take anywhere from 24 hours to several weeks depending on ambient temperature, weather conditions, the thickness of the layer applied, and the type of mix used.

It’s important to note that during this period, no vehicular or foot traffic should be allowed on the newly laid asphalt. Any weight placed on the soft surface may cause damage and affect its overall quality. Additionally, rushing through cure time by applying sealant or paint before full cure may lead to bubbling or cracking due to trapped moisture underneath.

The duration of asphalt curing also depends heavily on weather conditions such as humidity levels and rain. Excessive moisture can prolong the curing process and hinder proper adhesion between layers if not adequately addressed. Therefore, it’s essential to consult with an experienced contractor who understands all aspects of asphalt repairs for optimal outcomes.

In conclusion, understanding the importance of proper asphalt curing procedures is critical for achieving long-lasting results when repairing or installing pavement surfaces. Rushing through this stage may result in costly mistakes down the line that could have been avoided with patience and attention to detail during the initial stages of construction. So always ensure you work with professionals who understand how critical good cure times are!

Factors Affecting Asphalt Drying And Curing Time

Temperature is one of the key factors in determining asphalt drying and curing time, as it affects everything from humidity to bitumen. Humidity, thickness, primer, and bitumen can also play a role in how quickly the asphalt dries and cures. Additionally, factors such as sub-base, traffic, sunlight, wind, rain, and air movement can also influence asphalt drying and curing time. Lastly, compaction, pavement type, additives, and substrate can all affect the asphalt drying and curing process.

Temperature

When it comes to the curing process of fresh asphalt, the temperature is a crucial factor that can make or break your project. Ambient and air temperature have a significant impact on how long it takes for asphalt to dry and cure properly. The wrong temperatures during hot weather conditions can be disastrous for your pavement.

Ideally, ambient temperatures should range between 60°F and 85°F for optimal curing results. If the air temperature exceeds this range, you’ll need to adjust your curing process accordingly. At high temperatures above 85°F, you’ll want to shorten your time between applications as much as possible. This will help prevent the surface from drying out too quickly before it has had a chance to fully adhere.

On the other hand, if the ambient temperature drops below 60°F, it’s best to wait until warmer weather arrives before laying down fresh asphalt altogether. When trying to cure in colder temperatures, you may find that the surface remains tacky even days later due to the lack of warmth needed for proper adhesion.

In summary, understanding how different temperatures affect asphalt curing times is essential knowledge for any paving contractor or DIY enthusiast looking to achieve excellent results with their projects. By keeping an eye on ambient and air temperatures, particularly in hot weather conditions, you can ensure that your freshly laid asphalt cures correctly without causing issues such as cracking or peeling over time.

Humidity

Now that we have discussed the impact of temperature on asphalt curing, let’s explore another critical factor: humidity. Humidity refers to the amount of moisture in the air and is a significant contributor to how long it takes for asphalt pavements to cure properly. High levels of humidity can cause issues during asphalt repair or new pavement installations by delaying the drying process, which can result in unsightly marks or an uneven surface.

When there is high humidity, water vapor collects on the surface and prevents it from evaporating quickly — this slows down the rate at which asphalt dries and extends the asphalt cure time. Additionally, if you install fresh asphalt when humidity is too high, excess moisture may become trapped underneath your surface, causing damage over time.

To avoid these complications caused by excessive humidity levels, contractors should monitor both ambient temperatures and relative humidity before starting any paving project. If weather conditions are unfavorable due to high humidity levels, consider postponing until more favorable conditions arise.

In summary, monitoring humidity levels plays an essential role in achieving excellent results with your asphalt repairs or installation projects. It is crucial to remember that while temperature affects how fast your asphalt cures; humidity also has a considerable impact on drying times. By keeping an eye on both factors and adjusting accordingly, contractors can ensure their work meets standards while preventing future damages caused by inadequate curing processes.

Average Asphalt Driveway Drying Time: When To Drive On It?

Factors Affecting Asphalt Drying Time: Temperature, humidity, and sunlight all play a role in how long it takes for asphalt to dry.

Different Asphalt Curing Times: The amount of time it takes for asphalt to dry depends on the thickness of the layer and the type of asphalt being used.

When to Drive on Asphalt: You should wait at least 24 hours before driving on newly-laid asphalt, and you should avoid using it for heavy vehicles for at least three days.

Factors Affecting Asphalt Drying Time

Asphalt pavements are popularly used for driveways, roads, and parking lots. They offer durability and longevity compared to other materials. However, these surfaces need time to cure before they can be used to their full potential. The asphalt cure time can vary depending on several factors.

One of the crucial aspects that affect asphalt drying time is the weather conditions. Hotter climates tend to speed up the curing process as it evaporates moisture content quickly from the surface. Conversely, cooler temperatures slow down the drying process leading to a longer wait period before you can use your driveway or road.

Another factor affecting asphalt curing time is its thickness. Thicker layers of asphalt will take more extended periods to dry completely than thinner ones due to increased thermal mass and less exposure to air. Additionally, if there is an underlying issue such as water accumulation underneath the pavement, this could extend the drying period even further.

Finally, proper maintenance techniques like regular asphalt repair and sealing can significantly affect how long it takes for your pavement to dry correctly. If you neglect repairs or ignore seal coating schedules altogether, you may end up with a slower curing process than usual.

In conclusion, knowing what influences asphalt cure times is essential in planning when you can start using your driveway or road again fully. Keep in mind that various factors come into play during the curing process; thus patience and understanding are key when waiting for your pavement’s complete cure cycle.

Different Asphalt Curing Times

Now that we’ve discussed the various factors affecting asphalt cure times, let’s take a closer look at the different drying periods for newly paved or repaired driveways. The average time it takes for an asphalt driveway to dry and be ready for use can range from two days up to a week, depending on several variables.

One crucial element in determining curing time is the type of liquid asphalt used during paving or repair. Some types of asphalt may harden faster than others, which could significantly reduce curing time. It’s essential to discuss with your contractor what kind of liquid asphalt they will be using as this affects how long you need to wait before driving on your new pavement.

Another factor contributing to varying drying times is surface temperature. Hotter temperatures speed up the curing process, while cooler weather slows it down. During hot summer months, freshly laid asphalt driveways may only require 24-48 hours to cure completely. On the other hand, during colder seasons like winter or fall, expect longer waiting periods due to decreased heat exposure.

Lastly, patching repairs also have their own set of rules when it comes to curing times. Small patches may only need less than a day before they’re ready for traffic again. But larger ones might take weeks since there are more layers involved in repairing significant damages such as potholes or deep cracks.

Asphalt paving has been a preferred choice among homeowners and contractors because of its durability and longevity over other materials. However, proper maintenance techniques are necessary to ensure that these surfaces serve their purpose effectively without compromising safety and convenience. Remember always to follow recommended guidelines given by professionals so that you don’t risk damaging your newly installed pavement prematurely!

When To Drive On Asphalt

Now that we’ve discussed the factors affecting asphalt cure times and how long it takes for a newly paved or repaired driveway to dry, let’s focus on the critical question: when can you drive on your new asphalt pavement? The answer depends on several variables such as weather conditions, the type of liquid asphalt used, and the extent of repairs done.

Extreme heat speeds up the curing process of asphalt pavements. During summer months, freshly laid driveways may only need 24-48 hours before they are ready for vehicular traffic. However, cold temperatures during the fall and winter seasons could prolong the drying time; expect longer waiting periods due to decreased heat exposure. It is crucial to consider this factor since driving too soon on uncured asphalt could cause significant damage to your pavement.

The type of liquid asphalt used also affects how long you need to wait before driving on your new surface. Some types harden faster than others, significantly reducing curing time. Discuss with your contractor what kind of liquid asphalt they will be using so that you know how long you should wait before parking or driving on your new driveway safely.

Lastly, the extent of repairs done determines how much time it needs to cure fully. Small patches may only require less than a day before being ready for traffic again while larger ones might take weeks since there are more layers involved in repairing extensive damages like potholes or deep cracks.

In conclusion, knowing when to drive on newly installed or repaired asphalt surfaces requires careful consideration. Waiting until the recommended time for asphalt cure is essential to maintain its durability and longevity over other materials without compromising safety and convenience. Remember always to follow recommended guidelines given by professionals so that you don’t risk damaging your newly installed pavement prematurely!

The Complete Drying Process Of An Asphalt Driveway

Surface temperature is key for an asphalt driveway to dry properly; it shouldn’t be too hot or too cold. Likewise, the base preparation is important for the asphalt to adhere to the surface it’s laid on. It needs to be compacted, graded and leveled. It’s crucial to get these steps right for the driveway to dry without any issues.

Surface Temperature

You may have just had your asphalt driveway repaired, but don’t be too quick to drive on it. The asphalt curing process is a crucial step you need to know before using the surface again. One of the factors that affect the dry time is surface temperature.

The ideal surface temperature for asphalt repair is between 50°F and 85°F. If the temperature drops below this range, the drying process slows down significantly, leading to delays in usage. On the other hand, if it’s too hot outside, above 85°F, the asphalt can become malleable and susceptible to damage from foot or vehicle traffic.

If you’re not careful about following these guidelines, surface damage can occur due to premature use or extreme weather conditions. This type of UV damage will lead to cracks and potholes forming much sooner than expected. It’s important to keep track of the daily temperatures when scheduling an appointment or waiting for repairs to finish so that there are no surprises later on.

In conclusion, knowing how surface temperature affects asphalt cure times is essential knowledge when repairing or installing driveways. Don’t let impatience get in the way of allowing proper drying time as doing so could result in costly repairs shortly after installation. Take advantage of good weather conditions by scheduling appointments during optimal temperatures for long-lasting results!

Base Preparation

Now that we have covered how surface temperature affects the asphalt curing time, let’s move on to another crucial aspect of installing or repairing an asphalt driveway: base preparation. Before any resurfaced asphalt is laid down, it’s important to ensure the base layer is properly prepared.

The first step in preparing a solid foundation for your new driveway is removing any existing debris and vegetation. This includes grass, rocks, and old pavement. Once the area is cleared out, the soil must be compacted using specialized equipment to create a firm sub-base. Without proper compaction, settling can occur over time due to heavy traffic or cold weather conditions.

After compaction, a layer of crushed stone should be added as well as a binder material like cement or asphalt emulsion. This provides additional support and stability while preventing water from seeping through to the sub-base. It’s essential for this layer to also be thoroughly compacted before moving onto the final step of laying down fresh asphalt.

By taking these measures during base preparation, you can prevent future cracking and potholes caused by poor drainage or weakened sub-bases. Remember that investing in quality workmanship during installation saves you money in repairs down the line. So always make sure you’re hiring experienced professionals who understand all aspects of creating a long-lasting driveway.

In summary, one cannot overlook the importance of proper base preparation when dealing with asphalt driveways. Compacting soil and adding layers of crushed stone and binder materials are vital steps towards ensuring dry asphalt will last many years without damage from harsh weather conditions or heavy traffic. By choosing skilled professionals who use high-quality materials and methods, homeowners can rest assured their driveways will withstand even the toughest wear and tear!

Identifying A Cured Asphalt Surface

Temperature variation is key when it comes to curing asphalt, as it impacts the rate of the curing process. Moisture content also needs to be taken into consideration, as too much can delay the curing. Furthermore, visual inspection is a great way to identify a cured asphalt surface, as it should appear darker, harder, and smoother. It’s important to keep in mind that different climatic conditions will affect the curing process too. Additionally, the asphalt should be tested for compaction and should be able to withstand traffic. Finally, curing time should be monitored carefully to ensure that the asphalt is cured correctly.

Temperature Variation

Asphalt parking lots are a common sight in many public and private spaces, but have you ever wondered how to tell if the asphalt is cured? One crucial factor that affects curing time is temperature variation. In cold weather conditions, dry asphalt has a slower drying time which means it may take longer to cure properly.

When resurfaced asphalt experiences colder temperatures during its initial curing period, there can be an increased risk of damage from foot or vehicle traffic. This is because the surface will not have had enough time to fully harden before being subjected to pressure. The lower the temperature, the more prolonged the curing process becomes. Therefore, it’s best to avoid using newly paved areas until they’ve been given ample time to cure and reach their full strength.

On the other hand, higher temperatures tend to speed up the curing process by accelerating evaporation of moisture within the asphalt mix. However, extreme heat can also cause cracks on the pavement as a result of thermal expansion. It’s important for contractors to monitor temperature fluctuations and adjust their installation procedures accordingly so that proper bonding between layers occurs without any issues.

In conclusion, understanding how temperature variation impacts asphalt curing times is essential knowledge when identifying whether an asphalt surface has cured completely or not. While cold weather poses challenges with slower drying times and potential risks for damage, hot climates bring about different concerns such as thermal cracking. By taking these factors into consideration and allowing sufficient time for curing processes under ideal conditions, we can ensure long-lasting durable surfaces for years to come.

Moisture Content

Now that we have discussed how temperature affects the curing time of asphalt, let’s move on to another crucial factor: moisture content. Moisture can be harmful to newly paved surfaces as it weakens the bond between layers and causes forms of damage such as potholes or cracks. When water penetrates through the asphalt sealant, it can also lead to more severe structural issues over time.

To prevent these problems from occurring, contractors must ensure proper drainage systems are in place before laying a layer of asphalt binder. They should also avoid installing asphalt during rainy or humid weather conditions. Moisture content is critical because even small amounts can penetrate deep into the surface and cause long-term harm.

In addition to rainfall, there are other sources of moisture that could affect newly installed pavement surfaces. For example, snowmelt runoff or irrigation systems may introduce water onto an already wet surface, causing further delays in the curing process. It’s important for contractors to monitor all possible sources of moisture and take necessary precautions to protect their work from any harmful elements.

Ultimately, understanding how moisture content impacts the curing process is essential when identifying whether an asphalt surface has cured completely or not. By taking steps to control environmental factors such as temperature and humidity levels, we can ensure that our pavement surfaces remain strong and durable for years to come without experiencing any unnecessary damage or deterioration caused by excessive moisture content.

Visual Inspection

Now that we have discussed the impact of temperature and moisture content on asphalt curing, let’s move on to another crucial factor: visual inspection. This is especially important when identifying a cured asphalt surface because it allows us to assess whether or not the pavement can withstand vehicle traffic and heavy trucks without experiencing damage over extended periods of time.

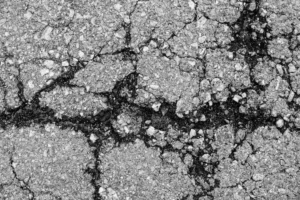

Visual inspection involves checking for signs of distress such as cracks, potholes, or rutting. These issues may indicate that the layer of asphalt will need repairs sooner than expected if left unaddressed. By taking preemptive measures through regular visual inspections, contractors can ensure their work maintains its curb appeal while also avoiding potential safety hazards for drivers and pedestrians alike.

To conduct an effective visual inspection, one should look closely at the surface texture and note any irregularities present—whether they are visible from afar or require closer examination. Some key things to consider include variations in color, smoothness, and overall appearance. Moreover, it’s critical to examine both sides of the road since different factors could affect each side differently.

Lastly, it’s worth noting that even after conducting a thorough visual inspection, there may still be underlying problems with an asphalt surface that aren’t immediately apparent. For this reason, routine checkups by professionals who specialize in identifying these sorts of issues are necessary to catch anything missed during an initial assessment. Ultimately though if caught early enough before significant wear sets in due to environmental conditions like moisture exposure then preventative maintenance techniques such as seal coating can help keep your pavement looking great year-round!

Precautions To Take While The Driveway Is Drying

After identifying a cured asphalt surface, it is important to take precautions while the driveway is still drying. Remember that freshly laid asphalt takes around 48-72 hours to cure completely, and during this period, it will be vulnerable to damage.

One of the most critical things you can do during this time is to avoid driving or parking on your new asphalt pavement. This action could leave tire marks on your newly paved surface, which may cause permanent damage. If possible, park your car in an alternative location until the curing process is complete.

Another precaution worth taking is avoiding sharp objects like high heels or bike stands from coming into contact with the asphalt surface. These items can easily puncture through the soft material and leave unsightly holes in your brand-new driveway.

It’s also essential not to apply any kind of sealant over wet or damp asphalt surfaces as this could lead to blistering and peeling off of the sealer once it dries up. Instead, wait for at least two days before applying an asphalt sealer to your dry driveway.

To protect your investment better, consider adding a thicker layer of asphalt than previously used when installing the pavement. The additional thickness gives more room for wear and tear without damaging the base layers underneath.

Precautions To Take While Your Driveway Is Drying:

Here are five tips to help ensure that your fresh coat of asphalt remains intact throughout its drying phase:

- Avoid driving or walking on freshly laid asphalt

- Keep sharp objects away from the surface

- Wait for at least 48-72 hours before applying any sort of sealant

- Park cars in alternate locations if possible

- Consider using a thicker layer of asphalt

Conclusion

In conclusion, understanding the difference between asphalt drying time and curing time is crucial for any homeowner. It can help prevent costly damages to your driveway and ensure its longevity. Additionally, it’s important to note that several factors affect how quickly or slowly asphalt cures.

As the old adage goes, “Patience is a virtue.” This rings true when waiting for an asphalt driveway to fully cure. Rushing through this process can lead to cracks, dips, or uneven surfaces in the future. Therefore, taking precautions such as avoiding heavy vehicles on the surface during the curing period will pay off in the long run with a durable and smooth driveway.

Write a call to action to ask the reader to read about asphalt compactions and surface treatments

If you’re interested in learning more about asphalt compaction and surface treatments, to ensure your driveway is properly installed, then read our article on the subject. With this knowledge, you can make sure your asphalt driveway is both durable and attractive.