Do you know what makes smooth and durable asphalt pavement? It’s not just about pouring hot asphalt mix on the surface and calling it a day. One crucial step in the process is asphalt compaction, which involves compressing the asphalt mix to achieve the desired density and stability.

Asphalt compaction is not a new technique, but it has evolved over the years with the advent of advanced equipment and technology. Today, there are various methods and machines used for asphalt compaction, each with its advantages and limitations.

In this article, we’ll delve into the world of asphalt compaction and explore the different techniques and tools used in the process. Whether you’re a contractor, engineer, or just a curious homeowner, this guide will provide you with valuable insights into the art and science of asphalt compaction.

What is Asphalt Compaction?

Asphalt compaction is a crucial process that ensures the stability and longevity of pavement installations. In simple terms, it involves compressing the asphalt layers to remove any air voids and achieve a dense, solid surface.

What is the significance of compacting asphalt during pavement installation?

Proper compaction increases the pavement’s durability, structural strength, and resistance to moisture and other damaging factors. A well-compacted pavement provides a smooth driving surface, prolonging its lifespan and requiring less maintenance.

The Basics of Successful Asphalt Compaction

Before diving into the details, let’s look at some fundamental aspects that influence successful asphalt compaction.

- Asphalt Mixture and Pavement Variables: The type and proportion of aggregates, binders, and additives used in the asphalt mix can affect compaction. The pavement’s structural design, including layer thickness and construction sequence, also plays a role.

- Aggregate Influences: The size, shape, texture, and gradation of aggregates determine their ability to interlock and compact efficiently.

- Volumetric Property Considerations: Factors like air voids, binder content, and aggregate gradation impact the pavement’s ability to achieve optimal density.

- Environmental Effects: Temperature and humidity can influence the compaction process and the pavement’s performance.

- Base Conditions: A well-prepared base allows for efficient compaction, ensuring the pavement’s structural integrity.

Factors Affecting Asphalt Compaction

Several factors directly impact the asphalt compaction process:

- Lift Thickness and Particle Size: The optimal lift thickness depends on the size of the aggregates in the asphalt mixture. Generally, thicker lifts are needed for larger particles to ensure proper compaction.

- Mix Temperature: The mix should be at the right temperature to achieve optimal compaction. If it’s too hot, the binder will be too fluid, and if it’s too cold, the mix will be too stiff.

- 5 Factors Affecting Density: The compaction process aims to achieve the desired density for the pavement. These factors include mix design, environmental conditions, roller selection, compaction techniques, and quality control procedures.

THREE PHASES OF ASPHALT COMPACTION

- PAVER SCREED COMPACTION PROCESS: The paver’s screed is responsible for initially leveling and compacting the asphalt mixture. It plays a significant role in the final density and smoothness of the pavement.

- ROLLER COMPACTION PROCESS: Rollers provide the primary compaction force, applying pressure and kneading the mixture to achieve the desired density. Different types of rollers are used for various stages of compaction.

- TRAFFIC COMPACTION PROCESS: Traffic loads on the pavement will cause additional compaction over time, further improving the pavement’s performance and durability.

Instructions on compacting asphalt pavements.

Asphalt can be compacted manually.

Hand compaction is a viable option for projects that are small in scale or difficult to reach with heavy equipment. The compaction process involves using hand tampers or vibratory plate compactors to compress the asphalt mixture.

Compacting Asphalt with a Machine

Machine compaction is used for most pavement installations. Rollers are the primary equipment used to compact asphalt, and they come in various types and sizes, such as static steel drums, pneumatic tires, and vibratory rollers.

Use a rolling train for the best results

A rolling train consists of a series of rollers that follow each other in a specific sequence to achieve the desired compaction. The train usually starts with a vibratory roller, followed by a pneumatic tire roller, and finishes with a static steel drum roller.

Roller speed matters.

The speed at which the roller moves affects the compaction quality. Slow speeds allow for better compaction, but they also increase the time needed to complete the process. Finding the right balance between speed and compaction efficiency is essential.

The Importance of Proper Compaction

Proper compaction is crucial to the overall performance of a pavement:

- Compaction Helps Minimize Fatigue-Related Pavement Damage: A well-compacted pavement resists fatigue cracking and deformation caused by traffic loads, reducing the need for costly repairs and maintenance.

- Proper Compaction Helps Minimize Moisture Damage: Densely compacted asphalt is less permeable, reducing the risk of water infiltration and damage caused by freeze-thaw cycles.

Asphalt Compaction Best Practices

Achieving the best results in asphalt compaction requires attention to several factors:

- 3 Temperature Zones: Asphalt compaction should be carried out within a specific temperature range, typically divided into three zones: lower, middle, and upper. The lower zone is the minimum temperature for compaction, while the upper zone represents the maximum temperature before the mix becomes too fluid.

- Echelon Rolling Takes Advantage of the Upper Zone: Echelon rolling involves using multiple rollers to compact the asphalt while it’s still in the upper-temperature zone, ensuring efficient compaction and a smooth, uniform surface.

What are the consequences of faulty compaction?

Inadequate compaction can lead to a variety of issues:

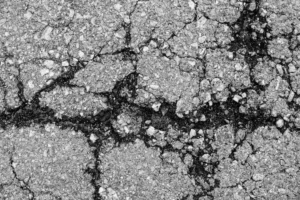

•Cracking: When asphalt is not properly compacted, it can settle unevenly, leading to cracking and surface deformation.

•Loss of Strength: Poor compaction reduces the strength of the asphalt which can lead to a variety of issues including reduced life expectancies for pavements, increased maintenance costs, and decreased function.

•Poor Drainage: Lack of compaction can also cause water to pool on the surface, leading to water damage and erosion.

•Potholes: Over time, cracks in the asphalt caused by improper compaction can become large holes known as potholes.

• Increased Costs: All these issues will result in increased costs for property

Conclusion: The Critical Role of Asphalt Compaction in Pavement Installation

Proper asphalt compaction is vital for achieving durable, long-lasting pavements that require minimal maintenance.

Understanding the factors affecting compaction and applying the appropriate techniques and equipment will ensure the best possible results.

By paying close attention to each step of the compaction process, you can significantly extend the life of your pavement and reduce the overall costs associated with its upkeep.

If you are looking to extend the life of your pavement, be sure to ask about asphalt curing times and make sure that your asphalt is properly compacted. Doing so will help ensure that your pavement is durable and long-lasting.