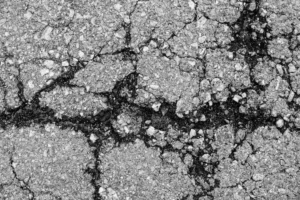

Have you ever noticed potholes, cracks, or other damage on your driveway or parking lot? Not only are they an eyesore, but they can also be dangerous for drivers and pedestrians.

Traditional asphalt repair methods can be time-consuming and costly, but there’s a more efficient solution: infrared asphalt repair.

Infrared asphalt repair uses infrared heating technology to heat the damaged area, allowing for easy removal and replacement of the damaged asphalt.

This method is not only quicker and more cost effective than traditional methods, but it also produces longer-lasting results.

In this article, we’ll dive deeper into infrared asphalt repair, discussing the benefits, process, and cost of this innovative solution to asphalt damage.

What Is Infrared Asphalt Repair?

Infrared asphalt repair is a great way to fix specific problems with your asphalt pavement without having to replace or resurface the entire surface.

It’s an efficient and cost-effective solution that uses infrared technology, an infrared asphalt heater, and fresh asphalt to restore any damaged areas.

The process requires less labor time than traditional methods and leaves no seams or joints for water to seep in.

Infrared repair: what’s good about it?

The benefits of infrared repair are many, and it’s no wonder that this method of asphalt repair is becoming increasingly popular.

First, infrared repairs are usually completed within a much shorter timeframe than traditional methods, meaning you can get back on track faster.

Additionally, the process requires fewer raw materials than other forms of asphalt repair, making it a more cost-effective solution. The heat penetration from the infrared rays also means that the existing asphalt won’t be burned or separated from the aggregate during the repair process.

This seamless patch helps to prevent water damage in the future by eliminating joints for water to seep into.

Finally, because there’s no need to wait for heated asphalt to cool off before driving on it, you can start using your new pavement almost immediately after repairs have been made.

With all these great advantages, it’s easy to see why infrared asphalt repair is quickly becoming a go-to choice for damaged pavement restoration!

Infrared asphalt repair is an efficient and cost-effective solution for restoring your pavement to its original condition.

Plus, with the added bonus of being able to start using your new pavement almost immediately after repairs have been made, it’s no wonder that this form of asphalt repair is becoming increasingly popular. But how does infrared repair work exactly? Stay tuned to find out!

How does infrared repair work?

Infrared asphalt repair is a relatively simple yet effective way of restoring damaged pavement to its original condition.

The process begins with an infrared heating unit which is placed above the area to be repaired. This heater warms the asphalt up to the correct temperature, allowing it to become workable again. Once heated, fresh asphalt can be added and spread evenly over the damaged surface.

The vibratory roller is then used to compact the new material in place, creating a seamless patch that offers a permanent solution for your damaged pavement.

Once complete, all that’s left is for oil spots on the surface to be cleaned up and any additional finishing touches made.

You’ll then have a brand-new-looking entryway or parking lot that you can start using immediately! Infrared asphalt repair offers a fast and efficient way of repairing your pavement without having to wait hours or days for heated asphalt to cool off before driving on it– making it the ideal solution if you need your pavement repaired quickly.

For a quick, effective solution to your asphalt repair needs, infrared asphalt repair is the way to go. Not only will it save you time and money, but you’ll have a quality finished product that looks like new in no time! And don’t forget: next up we’ll dive into some of the common applications of infrared asphalt repair.

The potential uses for infrared asphalt repair.

Infrared asphalt repair can be used for a variety of repairs, from small divots and dips to larger areas. Common applications include repairing potholes, patching joints for water entryways, and filling in low spots or uneven surfaces. It’s also great for filling in cracks or small holes where water can seep through.

The infrared asphalt repair process is relatively simple; it begins with an infrared heater being placed over the area to be repaired. This heats up the asphalt until it reaches its optimal temperature for workability. Then fresh asphalt is added and spread evenly over the damaged surface before being compacted with a vibratory roller.

Overall, infrared asphalt repair is a cost-effective solution that offers permanent results without having to wait hours or days for heated asphalt to cool off before driving on it– making it ideal if you need your pavement fixed quickly!

If you’re looking to get your pavement repaired fast and efficiently, then infrared asphalt repair may just be the perfect solution for you!

The pros and cons of infrared asphalt repair.

Infrared asphalt repair is a popular and cost-effective solution for many common pavement repairs. But just like anything else, there are both advantages and disadvantages to using this technology.

Infrared Asphalt Repair Pros

Infrared asphalt repair is a great choice for any pavement project! It offers many advantages, such as seamless patching with no visible seams between the new asphalt and existing surface, fast drying so you can drive on it almost immediately after installation, and reduced material costs.

Additionally, since infrared heat penetrates deep into the asphalt, it helps create a strong bond between the aggregate subsurface and the new asphalt. This prevents moisture damage and allows for easy installation of speed bumps in parking lots or roads.

Overall, infrared asphalt repair is an excellent option if you need to make pavement repairs. It’s cost-effective and produces great results without disturbing existing surfaces or burning or scaling them. So why not give infrared asphalt repair a try? You won’t regret it!

Infrared Asphalt Repair Cons

While infrared asphalt repair is a great option for pavement projects, it does have some drawbacks. First, it’s not a permanent solution; after enough time passes, the asphalt will eventually break down and require total replacement.

Additionally, it can’t be used to repair more severe issues like extensive networks of alligator or fatigue cracks. And finally, while it’s perfect for small surface-level potholes and other minor imperfections, it won’t help with exposed potholes that require the removal of the surface around the hole itself.

These limitations can make infrared asphalt repair an impractical choice in certain situations. But if you’re looking for a fast and cost-effective way to patch up small areas of your pavement? It’s definitely worth considering!

Should you choose Infrared Asphalt Repair?

Infrared asphalt repair is a great way to quickly and cost-effectively patch up small areas of pavement without having to replace the entire surface.

Utilizing infrared technology, workers can mix existing asphalt with new or recycled asphalt to create a seamless patch that looks just like the original surface.

This makes it perfect for parking lots and entryways where an aesthetically pleasing look is important.

Additionally, infrared asphalt repair can be used to add items to the surface like speed bumps and rumble strips, making it an environmentally friendly tool for any paving project.

However, infrared asphalt repair isn’t a permanent solution; eventually, the asphalt will break down and require complete replacement.

It also can’t be used for more severe issues like extensive networks of alligator or fatigue cracks, nor can it help with exposed potholes that require removal of the surrounding surface.

But if you’re looking for a fast and cost-effective way to patch up small areas of your pavement? Infrared asphalt repair may be worth considering!

Infrared asphalt repair is a great way to quickly and cost-effectively fix up small areas of your pavement without breaking the bank.

But when should you use this technology for your asphalt repair needs? Find out in the next section!

When should you use infrared repair for asphalt?

When it comes to asphalt repair, infrared technology is a great way to quickly and cost-effectively patch up small areas of pavement without having to replace the entire surface.

While it’s not a permanent solution, infrared asphalt repair can be an excellent choice for simple repairs like potholes, pavement heaving, and uneven or rough driving surfaces.

It can also be used to add items like speed bumps and rumble strips, making it an environmentally friendly option.

If you’re looking for a fast and cost-effective way to patch up small areas of your pavement with minimal disruption while still maintaining an aesthetically pleasing look, then infrared asphalt repair might be worth considering!

Of course, it’s important to identify exactly what type of issue you’re dealing with so that you know whether or not an infrared repair is the right choice for your project.

If you’re uncertain about which route to take, consult with an experienced paving contractor like Nathan’s Paving. We can help you make the best decision for your needs.

Infrared asphalt repair can help you quickly and cost-effectively patch small areas of your pavement with minimal disruption, making it an ideal choice for many projects.

Conclusion

An infrared asphalt repair is a great option for quickly and cost-effectively patching up small areas of pavement with minimal disruption.

It’s an environmentally friendly choice that can be used to add items like speed bumps and rumble strips, as well as repair potholes, pavement heaving, and uneven or rough driving surfaces. While infrared repairs are not permanent, they can provide a seamless patch that will last until the area needs to be resurfaced.

That said, it’s important to consider the pros and cons of infrared asphalt repair before deciding if it’s the right solution for your project. The biggest advantage is its quick turnaround time; however, this might also be a disadvantage since it doesn’t offer as long-lasting of a result as other methods do.

Additionally, the infrared heater must be smaller than the size of your patch in order to ensure that all edges are heated properly for a seamless finish.

Finally, you’ll need to ensure that you have enough space around your damaged asphalt surface so that you have easy access to use an infrared heating unit safely.

Overall, infrared patching can be a great solution for quickly and cost-effectively patching up small areas of pavement with minimal disruption.

If you want to ensure that your asphalt surfaces last longer and look great, then take action now! Read our blog post on asphalt maintenance to learn the essential steps to maintaining your asphalt surfaces. Start making a difference today and keep your asphalt surfaces looking their best!