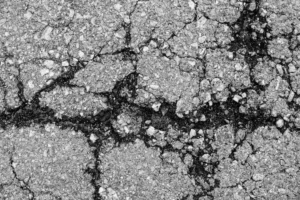

Are you tired of seeing cracks mar the smooth surface of your asphalt pavement? Well, fret no more!

In this article, we will guide you through a variety of effective crack repair techniques that will leave your pavement looking brand new.

From crack assessment and preparation to hot pour crack sealing and overlays, we’ve got you covered.

Get ready to learn the secrets of restoring your asphalt to its former glory.

Key Takeaways

- Evaluate the severity and extent of the cracks

- Choose the right material for the job (cold patch, hot mix asphalt, asphalt emulsion)

- Clean the crack thoroughly before applying the sealant

- Routing and sealing cracks provide a more effective and long-lasting repair

Crack Assessment and Preparation

Assess the cracks in your asphalt pavement and properly prepare them for repair. When it comes to crack repair methods, it’s crucial to first evaluate the severity and extent of the cracks. Inspect the width, length, and depth of each crack, as well as any underlying issues such as water damage or structural instability. This assessment will determine the appropriate repair technique for each crack.

Once the assessment is complete, the next step is preparation. Begin by cleaning the cracks thoroughly, and removing any debris or vegetation that may hinder the repair process. It’s also important to apply crack prevention techniques, such as sealing and filling the cracks, to prevent further damage and prolong the lifespan of your asphalt pavement.

Cleaning the Crack

To clean the crack, start by removing any debris or vegetation that may hinder the repair process. This step is crucial in ensuring a successful crack repair. Debris such as loose asphalt, stones, and dirt must be thoroughly cleaned out to allow for proper adhesion of the repair material.

Use a wire brush or a broom to sweep away loose particles.

Next, use a high-pressure air compressor to blow out any remaining debris and ensure a clean surface.

It’s important to note that crack-cleaning techniques may vary depending on the size and condition of the crack. However, regardless of the technique used, crack preparation is essential for achieving a durable and long-lasting repair.

Filling the Crack With Asphalt Patching Material

Once the crack has been thoroughly cleaned, proceed to fill it with the appropriate asphalt patching material. Asphalt crack repair requires careful attention to detail and the use of effective crack filler techniques.

The first step is to choose the right material for the job. There are various types of asphalt patching materials available, such as cold patches, hot mix asphalt, and asphalt emulsions. Cold patch is a popular choice for repairing small cracks, while hot mix asphalt is recommended for larger cracks or areas with heavy traffic. Asphalt emulsion is a good option for filling narrow cracks and preventing water penetration.

Once the material is selected, carefully pour it into the crack, ensuring that it completely fills the void. Use a trowel to smooth out the patching material and create a seamless finish.

Following these techniques will ensure a durable and long-lasting repair.

Applying Crack Sealant

To effectively repair asphalt cracks, you need to apply crack sealant using the right technique. Properly sealing cracks is crucial to prevent water infiltration and further damage to the pavement. Here are three essential sealing techniques to ensure effective crack prevention:

- Clean the crack: Before applying the sealant, make sure to clean the crack thoroughly. Use a wire brush or compressed air to remove any debris or loose materials. This step ensures proper adhesion of the sealant to the asphalt surface.

- Apply the sealant: Use a handheld pour pot or a melter applicator to apply the crack sealant. Start from one end of the crack and work your way down, filling the crack completely. Be careful not to overfill, as excess sealant can create a bump on the surface.

- Smooth and level the sealant: After applying the sealant, use a squeegee or a trowel to smooth and level the sealant with the surrounding pavement. This step ensures a seamless finish and improves the overall appearance of the repaired crack.

Hot Pour Crack Sealing

Start by heating the crack sealant to the recommended temperature for hot pour crack sealing. This process involves melting the sealant in a specialized melter applicator, ensuring that it reaches the optimal temperature for application.

Hot pour crack sealing offers several advantages over cold pour crack sealing. Firstly, it provides a more durable and long-lasting repair as the hot sealant effectively bonds with the asphalt surface, creating a tight seal. Secondly, hot pour crack sealing has a faster curing time, allowing for quicker traffic reopening. Lastly, it is more suitable for larger and wider cracks, as the hot sealant can flow into the crevices more effectively. Here is a comparison between hot-pour crack sealing and cold-pour crack sealing:

| Hot Pour Crack Sealing | Cold Pour Crack Sealing | |

|---|---|---|

| Durability | High | Low |

| Curing Time | Fast | Slow |

| Crack Size | Suitable for larger and wider cracks | Suitable for smaller cracks |

| Bonding | Strong bond with asphalt surface | Weaker bond with asphalt surface |

Hot pour crack sealing is an effective technique that ensures long-lasting repairs for asphalt cracks.

Cold Pour Crack Sealing

Begin by preparing the cold pour crack sealing material according to the manufacturer’s instructions. Cold pour crack sealing is an effective method for repairing asphalt pavement cracks, providing long term durability and minimizing the need for costly repairs in the future.

Here are three maintenance tips to ensure successful cold pour crack sealing:

- Clean the crack thoroughly: Use a wire brush or high-pressure air to remove any debris or loose particles from the crack. This will ensure proper adhesion of the sealing material.

- Apply the cold pour crack sealant evenly: Use a pour pot or a crack bander to apply the sealing material into the crack. Make sure to fill the crack completely, leaving no gaps or voids.

- Allow sufficient curing time: Follow the manufacturer’s recommendations for curing time. This will ensure that the sealing material has enough time to bond with the surrounding asphalt and provide long-lasting protection against water infiltration and further damage.

Routing and Sealing Cracks

To effectively repair asphalt pavement cracks, you should begin by routing and sealing the cracks. Routing involves cutting a groove along the crack to create a reservoir for the sealant, while sealing involves filling the groove with a hot rubberized crack sealant. This technique is highly recommended for larger cracks as it provides a more effective and long-lasting repair.

Routing and sealing cracks require the use of specialized crack repair equipment such as routers and crack sealers. Routers are used to create the groove, while crack sealers are used to fill the groove with the sealant.

Before performing routing and sealing, it’s important to conduct a crack repair cost analysis. This analysis helps determine the most cost-effective approach for crack repair based on factors such as the size and severity of the cracks, the traffic load on the pavement, and the expected lifespan of the repair.

Crack Filling With Rubberized Asphalt

To effectively fill cracks in asphalt pavement, you should use rubberized asphalt. This material offers several benefits that make it an ideal choice for crack filling.

Here are three key reasons why rubberized asphalt is a superior option compared to alternative crack filling methods:

- Enhanced durability: Rubberized asphalt is made by blending asphalt with crumb rubber, which is derived from recycled tires. This combination results in a highly flexible and durable material that can withstand the stresses and movements of the pavement.

- Superior adhesion: Rubberized asphalt has excellent adhesion properties, allowing it to adhere tightly to the sides of the crack and create a strong bond. This prevents water and debris from entering the crack, reducing the risk of further damage and prolonging the lifespan of the pavement.

- Cost-effective solution: While rubberized asphalt may have a slightly higher upfront cost compared to alternative options, its long-lasting performance and reduced maintenance requirements make it a cost-effective choice in the long run.

Overlays and Resurfacing Techniques

To further improve the condition of your asphalt pavement, consider utilizing overlays and resurfacing techniques. These methods provide effective solutions to enhance the durability and appearance of your pavement.

When it comes to asphalt overlay alternatives, there are a few options to choose from. One popular alternative is a thin overlay, which involves applying a thin layer of asphalt over the existing pavement. This method is cost-effective and can help extend the lifespan of your pavement by providing a new, smooth surface.

Resurfacing techniques offer several benefits. Firstly, they can help restore the structural integrity of your pavement by covering up any cracks, potholes, or other surface defects. This not only improves the appearance of your pavement but also prevents further damage from occurring.

Secondly, resurfacing can enhance the skid resistance of your pavement, improving safety for both pedestrians and vehicles. Lastly, resurfacing can give your pavement a fresh, new look, increasing the overall aesthetic appeal of your property.

Conclusion

Overall, effective asphalt paving crack repair techniques are essential for maintaining the integrity and longevity of roads and pavements.

By properly assessing, preparing, and filling cracks with asphalt patching material, applying sealant, and utilizing hot or cold pour crack sealing methods, professionals can ensure a durable and smooth surface.

Additionally, employing routing and sealing techniques, as well as using rubberized asphalt for crack filling, can further enhance the repair process.

Ultimately, these methods act as the stitches that mend the wounds of the asphalt, prolonging its life and functionality.