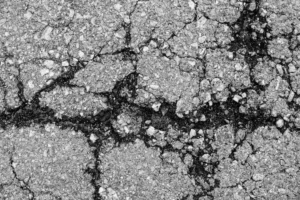

You’re dealing with alligator cracking, a network of interconnected cracks resembling alligator skin. It results from excessive loads, improper pavement thickness, poor drainage, and aging. Early signs include hairline fractures and surface deformation, with moisture infiltration worsening the damage. This cracking compromises road safety, leading to potholes and reduced traction. Addressing structural issues, like excessive traffic loads and poor construction practices, can prevent it. Effective repair methods include patching, milling, and overlaying, considering the extent of damage. Regular inspections and maintenance, such as sealcoating and proper drainage, mitigate risks. Keep exploring to understand thorough repair strategies and cost considerations.

Key Takeaways

- Alligator cracking is a network of interconnected cracks in asphalt resembling an alligator’s skin, indicating severe pavement distress.

- Common causes include excessive load, inadequate pavement thickness, poor drainage, and improper installation.

- Early signs include hairline fractures, surface deformation, and moisture infiltration, leading to safety issues and accelerated deterioration.

- Effective repair methods include patching, filling, milling, overlay, and crack sealing, depending on damage extent.

- Long-term maintenance involves regular inspections, timely repairs, proper drainage design, quality construction, and sealcoating.

What Is Alligator Cracking

Alligator cracking, sometimes called fatigue cracking, is a prevalent type of asphalt damage that manifests as a network of interconnected cracks resembling alligator skin. You’ll typically find this damage on driveways, parking lots, and roads, especially in high-traffic areas. The size of these cracks can range from a couple of feet to several meters, indicating varying degrees of severity in pavement distress.

Understanding the causes of alligator cracking is important for effective pavement management. Heavy traffic loads, poor drainage, structural design deficiencies, and construction issues are primary contributors to this type of damage. These factors collectively reduce the structural integrity of the asphalt, making it more vulnerable to further deterioration and potentially leading to potholes.

To address and prevent alligator cracking, you should consider several repair options and preventive measures. Repair methods include full-depth patching, partial-depth patching, milling, overlay, and crack sealing. Preventive strategies involve regular inspections, ensuring proper design, maintaining quality construction practices, and timely repairs.

Additionally, improving pavement drainage can greatly mitigate the risk of alligator cracking, enhancing the longevity of the asphalt surface.

Causes of Alligator Cracking

Understanding the root causes of alligator cracking is vital for effective pavement management and long-term maintenance. To effectively treat alligator cracking, you must first evaluate the damage to identify the underlying issues.

One of the primary causes of alligator cracking is excessive load on the asphalt surface. When your pavement experiences heavy traffic loads beyond its design capacity, it begins to fatigue, leading to cracks.

Another significant factor is inadequate pavement thickness. If the asphalt layer isn’t thick enough to support the weight it carries, it will deteriorate prematurely.

Additionally, poor drainage is a common culprit. When water infiltrates the pavement structure, it weakens the sub-base and causes moisture-related cracks.

Improper installation practices also contribute to alligator cracking. Without a well-prepared sub-base and proper compaction, the pavement’s structural integrity is compromised.

Aging pavement, naturally, increases the susceptibility to cracking as it loses its flexibility over time.

Early Signs to Watch

One of the earliest signs of alligator cracking in asphalt is the appearance of small, interconnected hairline fractures on the surface, often in areas subjected to high traffic loads. Recognizing these early indicators is vital to effectively repair alligator cracking and maintain the integrity of the asphalt pavement surface.

To detect early signs, you should regularly inspect the pavement, especially in high-stress zones. Here’s what to look for:

- Hairline Fractures: Small, fine cracks forming a web-like pattern.

- Localized Distress: Cracking primarily in areas of frequent heavy loads.

- Moisture Infiltration: Signs of water seeping into the cracks, often leading to further damage.

- Surface Deformation: Slight depressions or unevenness around the cracks indicating structural issues.

These early signs often result from the causes of alligator cracking, such as inadequate drainage or heavy traffic loads. By identifying these indicators early, you can implement measures to prevent alligator cracking from worsening.

Regular maintenance and timely repairs are essential to extend the pavement’s lifespan and avoid costly overhauls. Don’t underestimate the importance of proactive measures—early detection and prompt action can save both time and resources in the long run.

Impact on Road Safety

Due to its detrimental impact on structural integrity, alligator cracking in asphalt greatly compromises road safety by increasing the risk of potholes and uneven surfaces. When the structural integrity of the pavement is compromised, it accelerates pavement deterioration, leading to hazardous conditions for drivers. Alligator cracking weakens the asphalt, making it more susceptible to developing potholes which can cause significant vehicle damage and increase the likelihood of accidents.

This type of pavement distress creates uneven surfaces that reduce traction and control, especially in adverse weather conditions. Drivers may encounter difficulty maneuvering through these compromised sections of the road, heightening the risk of losing control of their vehicles. Additionally, the presence of alligator cracking can lead to sudden jolts and vibrations, distracting drivers and potentially causing loss of vehicle stability.

Neglecting alligator cracking can result in severe road hazards, contributing to accidents, injuries, and property damage. Timely identification and repair of alligator cracking are essential in maintaining road safety. By addressing these issues promptly, you can prevent further pavement deterioration and maintain a safer driving environment.

Proactive maintenance measures are vital to uphold the structural integrity of asphalt and mitigate risks associated with alligator cracking.

Structural Issues Involved

Addressing the safety hazards posed by alligator cracking necessitates a deep understanding of the underlying structural issues contributing to this type of pavement distress. Alligator cracking is caused by several critical structural failures that you need to know to effectively address the problem.

Firstly, excessive traffic loads are a primary source of the problem. When the pavement is subjected to loads beyond its design capacity, it results in stress and fatigue, leading to cracking.

Secondly, poor construction practices can greatly compromise the integrity of the pavement. Inadequate compaction, substandard materials, or insufficient thickness can all contribute to early pavement failure.

Thirdly, drainage problems play an important role. Water infiltration weakens the pavement structure, leading to the formation of damaged areas. Proper drainage systems are essential to prevent moisture from seeping into the pavement layers.

Lastly, moisture infiltration due to lack of maintenance is a significant factor. Regular inspection and timely repairs are necessary to prevent water from penetrating and weakening the structural layers.

Understanding these structural issues involved is essential for identifying the root causes of alligator cracking and implementing effective repair strategies. By addressing these key factors, you can mitigate the extent of the damage and extend the lifespan of your pavement.

Effective Inspection Methods

How can you accurately assess the extent of alligator cracking in asphalt?

To start, you’ll need to conduct a thorough visual inspection. This involves systematically looking for interconnected cracks that mimic alligator scales. By identifying the size and density of these cracks, you can gauge the significance of the distress.

For a more structured approach, use a crack rating system. This system classifies alligator cracking into different severity levels, typically ranging from low to high. Low significance might involve minimal cracking that doesn’t affect the pavement’s structural integrity, while high significance indicates extensive cracking that compromises the surface’s stability.

Early detection is important. Regular inspections help catch alligator cracking in its initial stages, allowing for timely interventions. Without early detection, minor issues can escalate into major problems, leading to costly repairs and potential safety hazards.

During your inspections, note the specific areas where cracking is prevalent. This data helps in understanding underlying causes and planning effective repairs.

Prevention Techniques

To effectively prevent alligator cracking in asphalt, you should implement regular maintenance inspections to catch issues early. Regular inspections allow you to identify minor problems before they escalate into severe alligator cracking. This proactive approach is key to maintaining the integrity and longevity of your pavement.

Here are some essential prevention techniques:

- Implement Regular Maintenance: Regular inspections and timely repairs are vital. Small cracks should be sealed promptly to prevent them from developing into alligator cracking.

- Ensure Proper Drainage: Water infiltration is a major cause of pavement deterioration. Ensuring that your asphalt surface has effective drainage systems will prevent water from weakening the subbase and causing cracks.

- Restrict Heavy Loads: Limiting the weight of vehicles on your pavement can greatly reduce the stress on the asphalt. This is especially important in preventing structural failures that lead to alligator cracking.

- Design for Expected Loads: Proper structural design tailored to anticipated traffic loads is essential. Using adequate materials and thicknesses based on expected loads helps prevent premature fatigue.

Repair Methods

When addressing alligator cracking in asphalt, you’ll find that various repair methods like patching, filling, milling, overlay, and crack sealing offer effective solutions to restore pavement integrity.

Patching is a straightforward asphalt repair technique where you cut out damaged areas and replace them with new asphalt, ensuring the surface regains its structural strength.

Filling involves applying sealant or hot rubberized crack filler to the affected areas. This method helps prevent further deterioration by sealing the cracks, thereby hindering water infiltration and extending the surface’s lifespan.

Milling is another effective repair method, where the top layer of the cracked asphalt is removed. The surface is then prepared for a new layer of asphalt, improving its overall condition and durability.

Overlay, though more extensive, involves adding a new layer of asphalt over the existing one, effectively covering alligator cracks and reinforcing the pavement structure.

Lastly, crack sealing is a preventive measure that targets smaller cracks. By sealing them with specialized materials, you can stop water from seeping in and causing further damage.

Each of these repair methods addresses different aspects of alligator cracking, ensuring a holistic approach to asphalt repair and surface restoration.

Cost Considerations

Addressing alligator cracking promptly can save you substantial repair costs, which otherwise may escalate to between $1 and $25 per square foot. The cost to fix alligator cracks in your pavement can vary greatly based on the severity and extent of the affected area. To give you a clearer picture, here are four primary cost considerations:

- Extent of Damage: Minor cracks might only require routine maintenance, like applying hot rubberized crack filler, while extensive damage may necessitate full-depth pavement reconstruction.

- Materials and Methods: Using hot rubberized crack filler is cost-effective for minor repairs, but more severe alligator cracking may require more expensive materials and techniques, such as asphalt overlay or complete removal and replacement.

- Labor Costs: The complexity of the repair method directly influences labor costs. Simple crack sealing is less labor-intensive compared to extensive reconstruction, which involves more manpower and specialized equipment.

- Preventative Measures: Investing in timely repairs and regular maintenance can prevent minor cracks from developing into severe alligator cracking, ultimately saving you from higher future costs.

Understanding these cost considerations ensures you’re well-prepared to maintain your pavement effectively, mitigating the risk of escalating repair expenses while extending its lifespan.

Long-Term Maintenance Strategies

Implementing long-term maintenance strategies for asphalt requires a proactive approach focused on regular inspections, timely repairs, and the use of high-quality materials. You need to conduct periodic inspections to identify early signs of alligator cracking. By addressing these issues promptly, you can prevent the progression of more severe damage.

Timely repairs, such as applying crack fillers, are vital in maintaining the integrity of the asphalt surface. Proper drainage design is essential to reduce water infiltration, which can weaken the pavement structure. Make sure to evaluate and maintain your drainage systems regularly to avoid water accumulation that exacerbates alligator cracking.

Quality construction practices, including the use of durable materials and skilled workmanship, are foundational to extending the lifespan of your asphalt surface. Sealcoating is another preventive measure you should consider. Regular applications of sealcoat protect the asphalt from environmental damage and slow down the aging process.

Crack filler applications are equally important, as they seal minor cracks before they expand into larger, more problematic ones. Engaging experienced asphalt paving contractors can provide you with tailored long-term maintenance strategies that address and prevent alligator cracking effectively, ensuring the durability and longevity of your pavement.

Frequently Asked Questions

How Do You Fix Alligator Cracks in Asphalt?

You should dig out the damaged areas, improve drainage, and reinforce the pavement structure. Apply new asphalt and compact it properly. For long-term results, consult trained experts to confirm all underlying issues are addressed thoroughly.

How to Prevent Alligator Cracking?

You prevent alligator cracking by ensuring proper sub-base preparation, improving drainage, and conducting regular inspections. Restrict heavy loads, research soil and traffic conditions, and seal minor cracks promptly to maintain the pavement’s integrity and durability.

What Is the Cause of Cracking and Alligatoring?

Imagine the pavement’s foundation crumbling like a house of cards. You’ll find that heavy loads, poor construction, and bad drainage cause alligator cracking. Analyzing these factors helps you pinpoint precise solutions and prevent further deterioration.

Can You Seal Alligator Cracks?

Yes, you can seal alligator cracks. First, clean and prepare the cracks thoroughly. Then, apply crack filler or sealcoating. Although it’s a temporary fix, this process can slow deterioration and protect the asphalt surface.

Conclusion

Now that you understand alligator cracking, it’s time to take action. Don’t let these cracks snake their way into deeper structural issues. By recognizing early signs and implementing effective prevention and repair strategies, you’ll safeguard the integrity of your asphalt.

Remember, neglecting these web-like fractures can lead to a cascade of problems, impacting road safety and increasing costs. Act now to preserve your pavement’s longevity and guarantee a smooth ride for all.

Get Your Free Quote Today, Central PA!

Don’t let alligator cracking disrupt your pavement and road safety. If you’re in Central PA, take action now with Nathan Paving’s expert services. From patching and overlay to sealcoating, we have the right solution to restore your asphalt’s integrity. Get your free quote today and ensure a smoother ride tomorrow. Visit our Asphalt Paving and Asphalt Repairs pages to learn more about our comprehensive services.