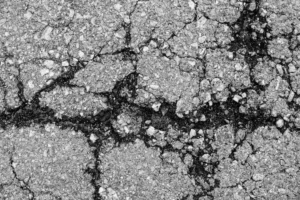

Did you know that over time, asphalt pavements can develop cracks that need to be repaired to prevent further damage? In this article, we will explore the various crack repair methods used in asphalt paving.

From patching and routing to crack filling and sealing, there are several techniques available to ensure the longevity of your pavement.

Whether you’re a homeowner or a professional in the industry, understanding these methods is crucial for maintaining the quality and safety of your asphalt surfaces.

Key Takeaways

- Crack sealing is important for ensuring a smooth and safe pavement, and it involves applying hot liquid asphalt material into the crack.

- Proper routing and preparation, such as cutting a groove along the crack and performing asphalt milling, can enhance the adhesion of the crack sealant and minimize cracks.

- Different crack filling methods, such as hot pour sealants, cold pour sealants, and emulsion-based sealants, should be chosen based on the severity of cracks and desired long-term durability.

- Hot pour sealants have superior adhesion and rapid curing, while cold pour sealants are suitable for smaller cracks and can be applied at ambient temperatures.

Patching

To patch cracks in asphalt paving, you can use various methods to effectively repair the damaged areas. Patching techniques are commonly used to address cracks in asphalt surfaces, ensuring a smooth and safe pavement.

One commonly used patching technique is known as crack sealing. This method involves applying a hot liquid asphalt material into the crack, which fills the void and prevents further water infiltration.

Another technique is called pothole patching, which is used to repair larger areas of damage. This involves removing the damaged asphalt, cleaning the area, and then filling it with a hot mix asphalt material.

Both crack sealing and pothole patching are effective methods for fixing common issues with asphalt paving, providing long-lasting repairs that enhance the durability and functionality of the pavement.

Routing

To effectively repair cracks in asphalt paving, one popular method that’s commonly used is called routing. Routing involves cutting a groove along the crack to create a reservoir that allows for better adhesion of the crack sealant. This technique is especially effective for larger cracks, as it provides more space for the sealant to fill in and bond with the surrounding asphalt.

Routing is typically done using specialized equipment, such as a router or a pavement cutter. The equipment is used to create a clean, uniform groove along the crack, ensuring that the sealant will adhere properly. Once the routing is complete, the crack is then cleaned and sealed with a high-quality crack sealant.

Asphalt milling is often performed prior to routing to prepare the surface and remove any damaged or deteriorated asphalt. This helps to ensure a smooth and even surface for the routing process.

Additionally, crack prevention techniques, such as proper drainage and regular maintenance, can help minimize the occurrence of cracks in asphalt pavement.

Crack Filling

You can fill cracks in asphalt paving using a variety of methods. Here are three options for crack filling that are commonly used in the industry:

- Hot pour sealants: These are heated to a liquid state and poured into the cracks. The sealant cools and solidifies, creating a durable and flexible barrier that prevents water infiltration and further damage. Hot pour sealants are known for their long-term durability and are often used for larger, more severe cracks.

- Cold pour sealants: These are typically used for smaller cracks and are applied at ambient temperatures. Cold pour sealants are easy to use and provide good crack prevention, but they may not be as durable as their hot pour counterparts.

- Emulsion-based sealants: These sealants are water-based and provide excellent crack prevention. They’re typically applied using a spray or squeegee and offer good long-term durability. Emulsion-based sealants are environmentally friendly and are often used for smaller cracks or as a preventive measure.

When it comes to crack filling, it’s important to consider the severity of the cracks and the desired long-term durability. Choose the method that best fits your specific needs and conditions to ensure a successful repair.

Crack Sealing

For crack sealing in asphalt paving, a commonly used method is the application of specialized sealants. Crack sealing is an effective technique that helps to prevent water infiltration and further damage to the pavement. By sealing the cracks, you can prolong the lifespan of the asphalt surface and reduce the need for costly repairs.

One of the benefits of crack sealing is that it creates a waterproof barrier, preventing water from seeping into the cracks and causing additional deterioration. This is particularly important in colder climates where water can freeze and expand, leading to more extensive damage.

There are different types of crack sealants available, including hot-applied sealants and cold-pour sealants. Hot-applied sealants are heated to a liquid state and then poured into the cracks, while cold-pour sealants are applied directly from the container. Both types of sealants offer excellent adhesion and flexibility, ensuring long-lasting crack sealing results.

Hot Pour Sealants

Hot pour sealants are a popular choice for crack repair in asphalt paving. They’re highly effective in preventing water infiltration and further damage to the pavement. Here are three key features of hot pour sealants:

- Superior adhesion: Hot pour sealants have excellent bonding properties, allowing them to adhere tightly to the edges of the crack and the surrounding pavement. This ensures a long-lasting repair that can withstand heavy traffic and extreme weather conditions.

- Flexibility: Hot pour sealants are designed to expand and contract with the pavement, accommodating temperature changes and preventing cracks from reappearing. This flexibility helps maintain the structural integrity of the asphalt surface.

- Quick curing time: Hot pour sealants cure rapidly, minimizing the downtime of the repaired area. Once applied and cooled, they form a durable, waterproof seal that can be trafficked within a short period.

Hot pour sealants are a reliable and efficient solution for crack repair, providing long-term protection for asphalt pavements.

Cold Pour Sealants

Moving on to another crack repair method used in asphalt paving, let’s now discuss cold pour sealants. Cold pour sealants are commonly used to fill and repair cracks in asphalt surfaces. These sealants are designed to be applied at ambient temperatures, making them convenient and easy to use.

One of the main benefits of cold pour sealants is their ability to be applied in any weather condition, including cold temperatures. This makes them a reliable option for crack repair throughout the year. Additionally, cold pour sealants have a quick curing time, allowing for faster completion of the repair process.

However, there are also some drawbacks to using cold pour sealants. They may not adhere as well to the asphalt surface compared to other methods, which can lead to reduced durability. Additionally, cold pour sealants may require frequent reapplication due to their lower resistance to wear and tear.

To ensure the best results when applying cold pour sealants, it’s important to follow certain best practices. This includes thoroughly cleaning and drying the crack before application, ensuring the sealant is properly mixed and heated, and applying the sealant in a uniform manner.

Crack Injection

To continue addressing crack repair methods used in asphalt paving, let’s now delve into crack injection. This method involves the use of specialized materials, such as epoxy or polyurethane, to fill and seal the cracks in the asphalt pavement. Here are three key points to understand about crack injection:

- Epoxy injection: This method involves injecting an epoxy resin into the cracks. The resin fills the cracks and hardens, creating a strong bond that helps prevent further cracking and water penetration. Epoxy injection is commonly used for larger or wider cracks.

- Polyurethane injection: Polyurethane is another material used for crack injection. It’s a flexible material that can expand and contract with the pavement, providing a durable and long-lasting repair. Polyurethane injection is often used for smaller or narrower cracks.

- Benefits of crack injection: Crack injection offers several benefits, including efficient and cost-effective repairs, improved pavement durability, and increased resistance to water intrusion. It also helps prevent further damage and extends the lifespan of the pavement.

Asphalt Overlays

Now let’s move on to another crack repair method used in asphalt paving, which involves the application of asphalt overlays.

Asphalt overlays are a common technique used for asphalt resurfacing and maintenance. This method involves placing a new layer of asphalt over an existing pavement surface to improve its condition and extend its lifespan.

The process starts with the preparation of the existing pavement, which may include cleaning, repairing any cracks or potholes, and ensuring a smooth surface.

Next, a layer of hot asphalt mix is applied and compacted using heavy machinery. This layer serves as a protective barrier, preventing water penetration and reducing further damage.

Asphalt overlays are a cost-effective solution to maintain and rejuvenate aging asphalt surfaces, providing improved durability and aesthetics.

Regular maintenance techniques, such as crack sealing and sealcoating, can further enhance the performance and longevity of asphalt overlays.

Preventive Maintenance

One important step in asphalt paving is to implement preventive maintenance measures. Preventive maintenance is crucial for ensuring the longevity and durability of asphalt pavements. By proactively addressing potential issues, preventive maintenance helps to prevent costly repairs and extends the lifespan of the pavement.

Here are three common preventive maintenance practices in asphalt paving:

- Regular inspections: Conducting routine inspections allows for the early detection of any signs of damage or deterioration. This enables prompt repairs to be made before the issues worsen.

- Crack sealing: Cracks in the pavement can allow water and other harmful substances to penetrate the surface, leading to further damage. Regularly sealing cracks helps to prevent moisture infiltration and stops the cracks from spreading.

- Surface treatments: Applying surface treatments, such as sealcoating or microsurfacing, helps to protect the asphalt from oxidation, UV rays, and other environmental factors. This helps to maintain the pavement’s integrity and appearance.

Implementing these preventive maintenance practices is essential to ensure the long-term performance and cost-effectiveness of asphalt pavements.

Conclusion

In conclusion, when it comes to crack repair in asphalt paving, various methods can be employed to ensure a durable and long-lasting solution.

Patching, routing, crack filling, and crack sealing are all important techniques that can be used to address cracks in the pavement. Patching involves removing and replacing damaged areas of the asphalt, while routing creates a clean and defined channel for crack fillers to be applied. Crack filling and crack sealing, on the other hand, involve filling the cracks with sealants to prevent moisture from seeping in and causing further damage.

Hot pour sealants and cold pour sealants are commonly used materials for crack repair. Hot pour sealants are heated and applied to the cracks, providing a flexible and watertight seal. Cold pour sealants, on the other hand, are pre-mixed and can be applied directly from the container, making them easier to use for smaller cracks.

In addition to these techniques, crack injection and asphalt overlays can also be used for more severe cases of cracking. Crack injection involves injecting a specialized material into the cracks to repair them from the inside out. Asphalt overlays, on the other hand, involve applying a new layer of asphalt over the existing pavement, effectively covering and sealing the cracks.

Finally, preventive maintenance is crucial in maintaining the integrity of the pavement. Regular inspections, timely repairs, and routine maintenance activities such as cleaning and sealing can help prevent cracks from forming and deteriorating.

By utilizing these techniques, one can effectively address cracks and prevent further deterioration, ensuring the longevity of the asphalt surface.