If you’re planning an asphalt paving installation, you know that proper techniques and considerations are crucial for a successful outcome.

With 14 tips at your disposal, you’ll be equipped to tackle the task with confidence.

From site preparation to long-term maintenance planning, this article will provide you with the technical knowledge you need to ensure a durable and long-lasting asphalt pavement.

So, let’s dive in and explore the world of asphalt paving together, shall we?

Key Takeaways

- Thorough site preparation is crucial for proper asphalt paving installation, including grading, soil stabilization, and compaction tests.

- Asphalt material selection should consider climate, traffic volume, and intended use, with higher-grade or modified asphalt mix options available for heavy traffic or extreme weather conditions.

- Proper mixing techniques and application methods, such as using the correct ratio of asphalt mix to aggregates and employing spray application or mechanical compaction, should be utilized.

- Attention should be given to compaction and rolling, edge and joint preparation, proper drainage, curing time and maintenance, sealcoating and surface protection, and traffic management for a successful asphalt paving installation.

Site Preparation

You should begin the asphalt paving installation process by thoroughly preparing the site. Site preparation is a crucial step that involves grading techniques and soil stabilization to ensure a solid foundation for the asphalt pavement.

Grading techniques involve shaping the site to the desired slope and level, allowing proper water drainage. This can be done using heavy machinery such as graders and rollers.

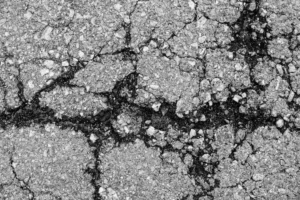

Soil stabilization is another important aspect of site preparation. It involves treating the soil to improve its strength and stability, preventing future issues like settling or cracks in the pavement. Common soil stabilization methods include compacting the soil, adding stabilizing agents like lime or cement, or installing geotextiles.

Proper site preparation sets the stage for a successful asphalt paving installation, providing a durable and long-lasting surface.

Base Layer Inspection

To begin the process of base layer inspection for asphalt paving installation, you should thoroughly assess the foundation for any potential issues or deficiencies. This step is crucial in ensuring a strong and durable pavement surface.

Here are three important aspects to consider during the base layer inspection:

- Grading Inspection: Check the grading of the base layer to ensure it meets the required specifications. Look for any uneven surfaces, low spots, or high areas that could affect the overall stability of the pavement.

- Compaction Testing: Perform compaction tests to verify that the base layer has been properly compacted. This is essential for achieving the desired density and strength. Use a nuclear density gauge or a sand cone test to measure the compaction levels accurately.

- Surface Smoothness: Assess the smoothness of the base layer to ensure it’s free from any irregularities. A smooth surface will promote proper bonding between the base layer and the asphalt overlay, resulting in a more even and durable pavement.

Asphalt Material Selection

Once you have completed the base layer inspection, the next step in asphalt paving installation is selecting the appropriate asphalt material.

The choice of asphalt material is crucial as it directly affects the pavement’s durability and the need for future maintenance. When selecting asphalt, consider factors such as climate, traffic volume, and intended use.

For areas with heavy traffic, a higher-grade asphalt mix with added aggregates may be required to withstand the constant wear and tear. In regions with extreme weather conditions, a modified asphalt mix that offers improved resistance to cracking and rutting is recommended.

Additionally, it’s important to consult with asphalt experts or suppliers to ensure the chosen material meets the specific project requirements.

Proper asphalt material selection is key to achieving a long-lasting pavement that requires minimal maintenance.

Temperature Considerations

When preparing for asphalt paving installation, you should consider the temperature conditions in order to ensure optimal results. Temperature variations and weather conditions play a crucial role in the success of the paving project. Here are three important factors to keep in mind:

- Ambient temperature: The temperature of the air can affect the overall performance of the asphalt. Extreme heat can cause the asphalt to soften and make it difficult to work with, while cold temperatures can lead to premature hardening and poor compaction.

- Surface temperature: The temperature of the existing surface where the asphalt will be applied is equally important. It should be within the recommended range specified by the manufacturer to ensure proper adhesion and durability.

- Weather conditions: Rain, snow, and excessive moisture can negatively impact the installation process. It’s crucial to schedule the paving project during a period of dry weather to prevent water from affecting the quality and lifespan of the asphalt.

Proper Mixing Techniques

First, ensure that you have the correct ratio of asphalt mix to aggregates. Proper mixing techniques are essential for a successful asphalt paving installation. To achieve the desired results, you need to use the right mixing equipment and follow the appropriate mixing ratios.

Mixing equipment, such as drum mixers or batch plants, should be chosen based on the specific project requirements. These machines ensure thorough mixing of the asphalt mix and aggregates, resulting in a uniform and consistent mixture.

The mixing ratio refers to the proportion of asphalt mix and aggregates used in the mixture. The correct ratio will depend on factors such as the type of asphalt mix, the desired pavement thickness, and the climate conditions.

Application Methods

To ensure a successful asphalt paving installation, you need to apply the mixture using the appropriate methods. Proper asphalt application techniques are crucial for achieving a smooth, durable, and long-lasting pavement. Here are three surface finishing methods that can help you achieve the desired results:

- Spray Application: This method involves the use of a specialized machine to spray the hot asphalt mixture onto the surface. It’s commonly used for large-scale projects and ensures an even and consistent application.

- Hand Tamping: For smaller areas or intricate details, hand tamping is often employed. It involves using handheld tools to manually compact the asphalt mixture, ensuring proper bonding and density.

- Mechanical Compaction: This method utilizes heavy machinery, such as rollers, to compact the asphalt and achieve the desired thickness and density. It’s commonly used for larger areas and provides efficient and uniform compaction.

Compaction and Rolling

For successful asphalt paving installation, ensure proper compaction and rolling of the asphalt mixture. Compaction techniques are crucial in achieving a durable and long-lasting pavement surface.

The primary goal of compaction is to eliminate air voids within the asphalt mixture, ensuring that it’s tightly packed and uniformly dense. This can be accomplished through the use of vibratory rollers or static steel-wheel rollers.

Vibratory rollers are effective in compacting the asphalt mixture by applying both vertical and horizontal forces, while static steel-wheel rollers are commonly used for finish rolling to achieve the desired smoothness.

When performing rolling procedures, it’s essential to follow a systematic pattern to ensure uniform compaction. Rolling should start from the edges and progress towards the center, overlapping each pass by half the width of the roller.

Edge and Joint Preparation

Proper edge and joint preparation is essential for achieving a seamless and durable asphalt pavement installation. It involves careful surface preparation and joint sealing to ensure the longevity and integrity of the pavement. Here are three important steps to follow:

- Clean and prepare the edges: Before paving, it’s crucial to clean the edges of the existing pavement thoroughly. Remove any debris, vegetation, or loose material. This will provide a clean surface for the new asphalt to bond to and prevent any potential cracking or separation in the future.

- Apply joint sealing: After the asphalt is laid, it’s important to seal the joints to prevent water infiltration and damage. Joint sealing involves applying a specialized sealant to the joints between the existing pavement and the newly laid asphalt. This will help maintain the structural integrity of the pavement and prevent premature deterioration.

- Ensure proper compaction: Along the edges and joints, it’s essential to ensure proper compaction. Use specialized tools to compact the asphalt and achieve a smooth, even surface. This will help prevent water penetration and maintain the strength and durability of the pavement.

Proper Drainage

To ensure effective water management and prevent damage to the asphalt pavement, it’s important to prioritize proper drainage during the installation process.

Proper drainage maintenance plays a vital role in preventing water accumulation on the pavement surface, which can lead to premature deterioration and costly repairs.

One key aspect of drainage maintenance is effective grading, which involves creating a slope that allows water to flow away from the pavement and into designated drainage areas. This prevents water from pooling on the surface and causing structural damage.

Additionally, regular inspection and maintenance of drainage systems, such as catch basins and culverts, is crucial to ensure proper water flow and prevent clogging.

Curing Time and Maintenance

Ensure that you allow an adequate amount of time for the asphalt pavement to be cured before conducting regular maintenance and usage.

Curing time estimation varies depending on factors such as temperature, humidity, and thickness of the asphalt layer. Generally, it takes around 24 to 48 hours for the asphalt to cure and be ready for regular use. However, it’s recommended to wait at least 72 hours before subjecting the pavement to heavy traffic or placing heavy objects on it.

During the curing period, it’s crucial to avoid any activities that could disturb or damage the newly laid asphalt.

Additionally, proper maintenance is essential to extend the lifespan of the pavement and minimize environmental impact. This includes regular cleaning, inspecting for cracks or potholes, and timely repairs to prevent water infiltration and further damage.

Sealcoating and Surface Protection

During the curing period, it’s important to protect the newly laid asphalt by applying a sealcoat and implementing surface protection measures.

Sealcoating is a crucial step in maintaining the longevity and durability of the asphalt pavement. It acts as a barrier against harmful elements such as water, UV rays, and chemical spills.

Before applying the sealcoat, thorough surface cleaning is necessary to remove any debris or dirt that may interfere with the bonding process. This can be done using a broom or a high-pressure washer.

Additionally, crack filling should be done prior to sealcoating to prevent water infiltration and further damage. It’s recommended to use a hot rubberized crack filler for optimal results.

Traffic Management

Protect your newly laid asphalt and ensure smooth operations by implementing effective traffic management strategies. Proper management of traffic flow is crucial during the asphalt paving installation process to minimize disruptions and maintain safety for both workers and motorists. Here are three key considerations for effective traffic management:

- Traffic Flow Control: Implement temporary traffic control measures such as signage, cones, and barricades to guide motorists safely around the work zone. This includes designating clear lanes and providing adequate warning signs to alert drivers of the upcoming construction activities.

- Detour Planning: Plan and communicate detour routes in advance to redirect traffic away from the construction area. Detour planning should consider the size and volume of traffic, alternative routes, and any potential impact on adjacent neighborhoods or businesses.

- Flagging Operations: Utilize trained flaggers to direct traffic and ensure a smooth flow of vehicles through the construction zone. Flaggers should be equipped with proper safety gear and follow standardized flagging procedures to maintain order and prevent accidents.

Implementing these traffic management strategies will help minimize disruptions, enhance safety, and ensure a successful asphalt paving installation process.

Quality Control Measures

To maintain the integrity of your asphalt paving installation, it is essential to implement rigorous quality control measures. Quality assurance plays a vital role in ensuring that your pavement meets the required standards and is durable enough to withstand heavy traffic and harsh weather conditions. This can be achieved through various testing procedures that assess the performance and quality of the asphalt mixture.

Testing Procedures for Asphalt Paving Quality Control:

| Testing Procedure | Purpose |

|---|---|

| Sieve Analysis | Determines the gradation and particle size of the aggregates |

| Asphalt Content | Measures the asphalt binder content in the mixture |

| Compaction Density | Checks the degree of compaction achieved during paving |

| Air Voids | Evaluates the amount of air voids in the asphalt pavement |

| Marshall Stability Testing | Determines the load-carrying capacity of the pavement |

Long-Term Maintenance Planning

How can you ensure the longevity and durability of your asphalt paving installation? Long-term maintenance planning is crucial for preserving the quality and integrity of your asphalt pavement. By implementing the following strategies, you can extend the lifespan of your asphalt and minimize long-term costs:

- Regular inspections: Conduct routine inspections to identify any signs of damage or deterioration, such as cracks or potholes, and address them promptly.

- Preventive maintenance: Implement preventive measures like seal coating and crack sealing to protect your asphalt from environmental factors and prevent further damage.

- Proper drainage: Ensure that your pavement has adequate drainage to prevent water accumulation, which can lead to erosion and structural issues.

Conclusion

Congratulations! You have now gained valuable insights on the art of asphalt paving installation. By following these 14 expert tips, you can ensure a smooth and durable pavement that will stand the test of time.

With proper site preparation, meticulous quality control measures, and long-term maintenance planning, your asphalt project won’t only impress but also provide a safe and reliable surface for years to come.

So go ahead, pave the way to excellence!